RIO DE JANEIRO, BRAZIL – Six questions to understand why Chile is a major lithium supplier to the world:

Read also: Check out our coverage on Chile

1. Where is it extracted, and in what ways?

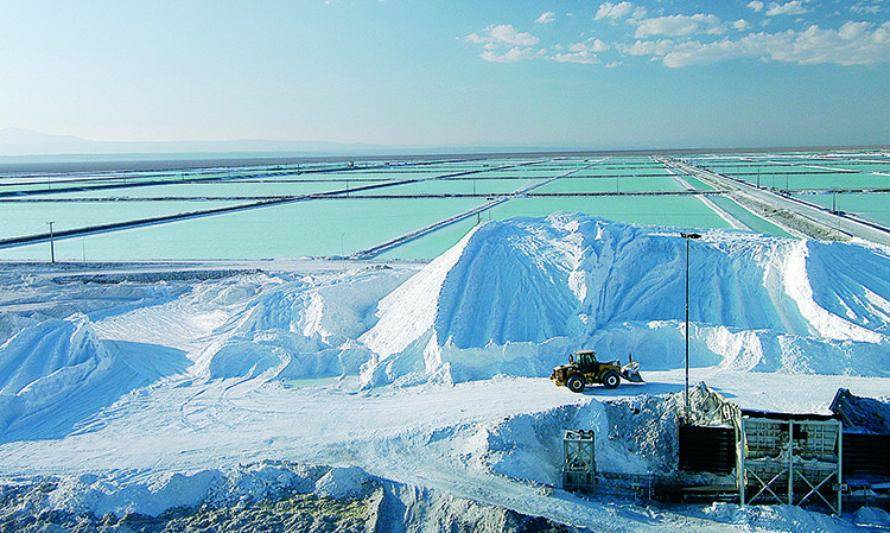

Chile’s race to produce lithium is one in which it competes against other countries in the region, such as Bolivia and Argentina. Lithium generally occurs in three forms: pegmatites, large minerals; brines in salt flats; and sedimentary rocks. Of these possibilities, it is in the brines where its greater presence in nature is observed, highlighting the north of Chile, Argentina, and Bolivia, the countries that present the main deposits in salt flats.

Currently, Chile is one of the world’s largest exporters of lithium and has a large percentage of the world’s reserves. However, the pegmatites contribute the most significant percentage of lithium production globally, with 55%, while brines contribute approximately 45%. The largest producer is Australia, with a market share associated with pegmatites of 48% by 2020, while the Salar de Atacama contributes 29% of world production, being a work concessioned to the companies SQM and the North American company Albemarle.

Lithium is extracted mainly in the Salar de Atacama, which has high solar radiation, wind, and dry air, favoring evaporation and has minimal rainfall in the Bolivian winter season, so the dilution of the brine in the solar pools is low. Thus, the production costs of obtaining concentrated lithium brines are low compared to processes that require energy sources other than solar energy, or as in the case of pegmatites, where power is consumed in the mineral comminution process.

2. Who are the main buyers of the mineral, and what are some of its multiple uses?

China is the leading consumer with 39% of world consumption. About 50% is used to make electric batteries. Japan consumes 26%, and South Korea 17%. Between these three Asian countries, consumption amounts to 93%, which translates into a series of products manufactured by a highly technological industry that supplies lithium-based products.

The most important use of lithium, which has led to its explosive demand and price in recent years, is the manufacture of rechargeable electric batteries. Electromobility possibilities for the design of light and heavy vehicles, e-bikes, scooters, and even other electric devices such as laptops, tablets, or phones, require lightweight, rechargeable, and portable batteries.

Other applications are related to the manufacture of glass and ceramics, providing mechanical properties avoiding the fracture of glass with heat, since, by incorporating lithium, they have a lower thermal expansion and lower fire temperature. The mineral can provide added value to the manufacture of air conditioners, life jackets, pharmaceutical products, plastics, and polymers, or the use of one of its isotopes in nuclear energy production.

3. Is Chile competitive with other producers?

Lithium generated in Chile has low production costs compared to brines generated in other latitudes. However, the production time is much longer since solar evaporation is a free but slow process of obtaining energy. These evaporative processes allow getting the product in one to two years, while a chemical-mining plant -for example, associated with Pegmatite- does it in one to two months. Chile is competitive in producing lithium carbonate or hydroxide.

It should be emphasized that there is a royalty applied to lithium that the producing companies pay and will continue to pay. When thinking about an industry linked to its extraction, lithium batteries use other components, and their assembly is made by several companies that generate their components. Producing batteries in Chile means competing with China and other emerging Asian manufacturers, which have a developed industry, experience and are very competitive. Proposing to produce batteries in Chile requires explaining how the industry of these goods could be developed competitively. In Chile, there is neither experience nor industry associated with the manufacture of the components of a lithium battery.

Chilean mining traditionally concentrates metals and acts as a supplier of raw materials. It is not trivial for business groups or the State to compete by creating national technologies with developed countries since the risk and investment are high. The question is whether Chile can produce better technologies than developed countries.

4. Why did the president-elect, Gabriel Boric, criticize the award of the Mining Ministry for the exploitation of 80,000 tons of lithium to the Chinese company BYD and the Chilean company Servicios y Operaciones Mineras del Norte S.A.?

The outgoing government considers that the private company has the experience and that, by paying a lithium royalty, they should continue to exploit the salt flats, assigning them greater annual production permits. That is possibly why Chile’s current president, Sebastián Piñera, wishes to accelerate this bidding process at the end of his government’s term.

Meanwhile, the future government wishes to review the conditions of these bidding contracts and evaluate whether the State can be more efficient in lithium production. In this sense, the idea of creating a National Lithium Company, a simile of Codelco, a company that has already started the exploration of this mineral in 2022, is generated.

We must ask ourselves whether the State can perform the task more efficiently and generate more benefits for the country. The answer is not trivial. Lithium in private hands works if the country is paid fair value for exploiting the non-renewable resources of Chilean soil, which cannot be free, especially if it generates environmental impact and affects communities, which must also be compensated.

However, given that the knowledge of exploitation is mainly in the industry and not in the State, the decision is not easy. It is reasonable for the new government to promote an exhaustive and meticulous study that allows its technical team to evaluate the pros and cons of these ideas. A Codelco simile could work for some metals produced in the country, but it requires an evaluation considering the multiple factors and actors involved.

5. How does the idea of creating a National Lithium Company look in the eyes of the scientific community?

People have in their minds the Codelco model, given that it is a successful state-owned company developed in the country. Codelco is a success, and one of its subsidiaries, Molyb, which processes Molybdenum and Rhenium, products that are subordinate to copper, have led Chile to have meaningful world participation. The copper industry is one of open information and easy access, with many professionals who know its processes and operations. The lithium industry is hermetic, with little information and few professionals who understand the production processes, posing a greater challenge since its methods are not related to conventional metal mining.

6. What is the impact on the ecosystem in lithium extraction, particularly on water, and is there any way to extract it without a major environmental impact?

The mining methods used to obtain lithium, its sustainability, how it affects the communities, and the retribution towards them and their environment should be reviewed. Lithium production consumes water resources in desert areas, given the extraction and evaporation of brine, without the recovery of evaporated water, reducing groundwater and lagoons’ water inventories in the area. Every mining process has an environmental impact.

Lithium processing can also be done by chemical routes, which increases production costs since, in this way, the advantage generated by the high radiation and dryness of the desert air is lost, in addition to the costs associated with redesigning the process. In the Atacama, it must possibly maintain its production employing solar ponds; however, it can optimize its production processes. In Maricunga, there is a possibility that the plant will be a chemical dye plant, given that these are rainier areas with higher air humidity, which could lead to thinking about other alternatives. Environmental conditions are an essential variable in the decision.

The academy has also studied lithium recovery processes by solvent extraction. However, these are ideas that are still under development, as well as expanding the productive capacity to brines of non-optimal composition for current solar evaporation ponds, using, for example, chemical conditioning of solar ponds, first adapting the chemical composition of the brines to be evaporated in the processes in the Atacama or other salt flats.